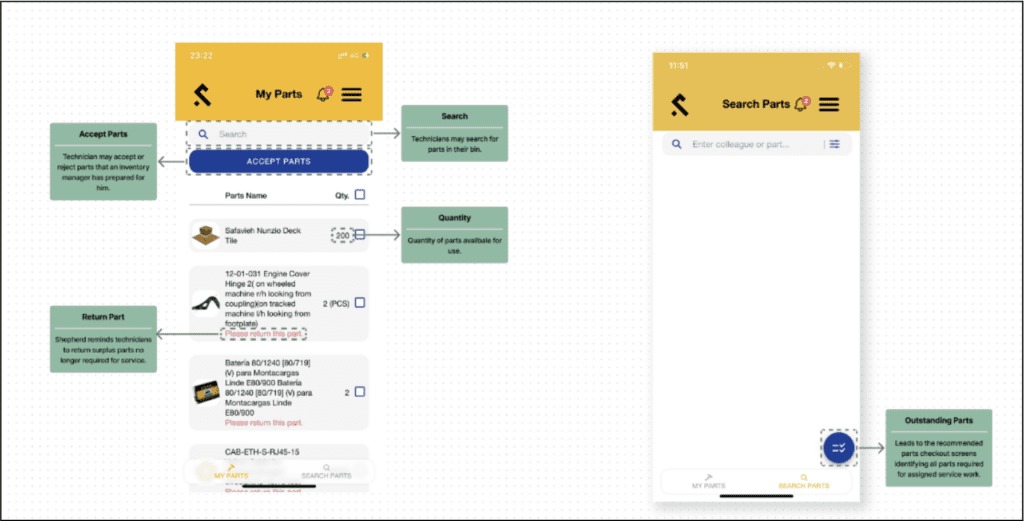

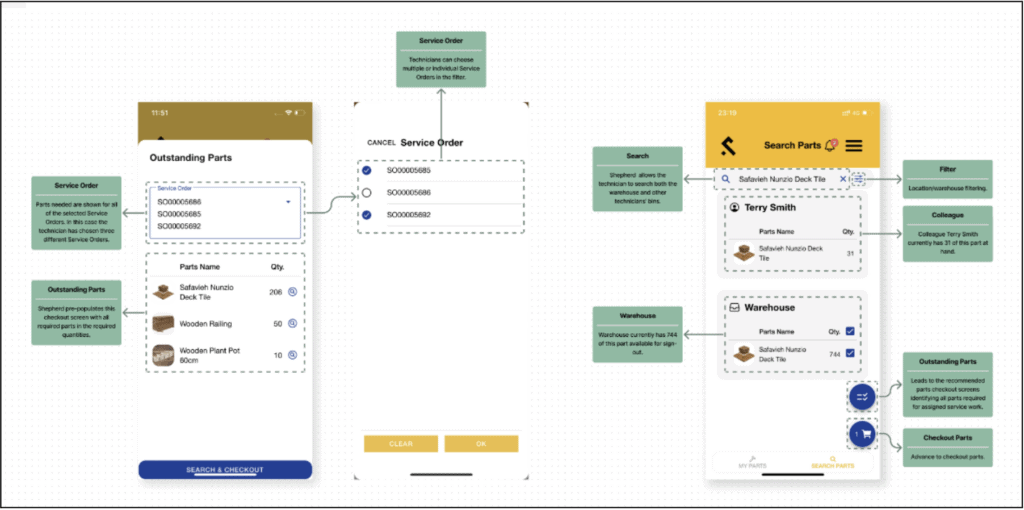

Shepherd reminds both employed and subcontracted installers to check-out the correct quantity of flooring before heading to the job site. The Shepherd mobile application analyzes all fulfillments for sales orders associated to those install service orders and compares those items and their quantities to each installer’s mobile stock of floor paneling. The result is an intelligent check-out screen whose purpose is to eliminate the occasion of incomplete installations due to insufficient material.

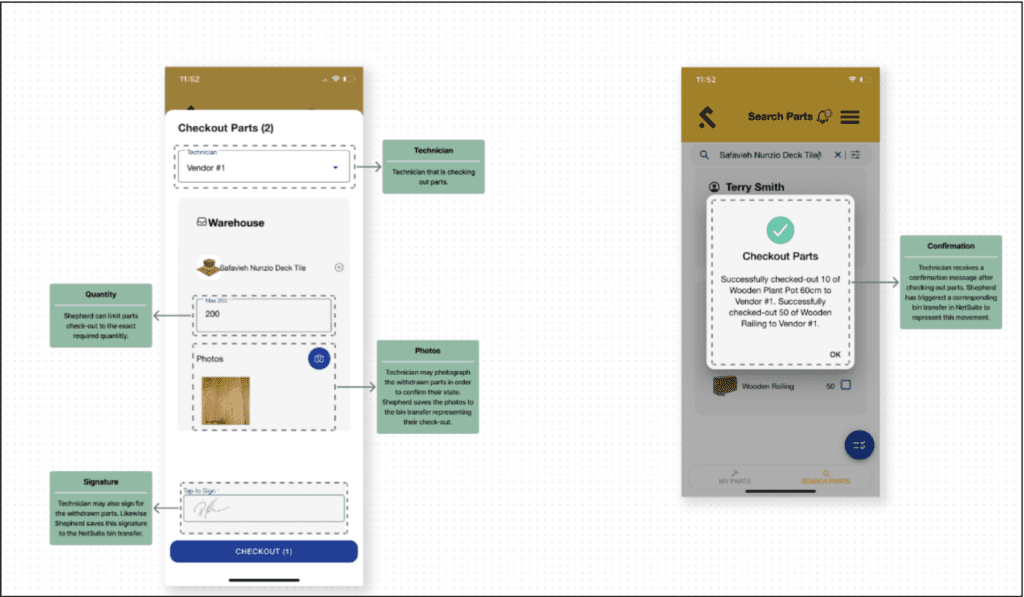

At parts check-out and acceptance, installers may both sign for and photograph the withdrawn floor panels in order to confirm and document the action. Because liability moves with the inventory and passes to its new custodian, these signature and photographs assist when and if audits become necessary. And even when an audit is not necessary the act of signing and photographing check-out part, often makes the installer more careful as he understands that an audit trail documenting that liability does exist.

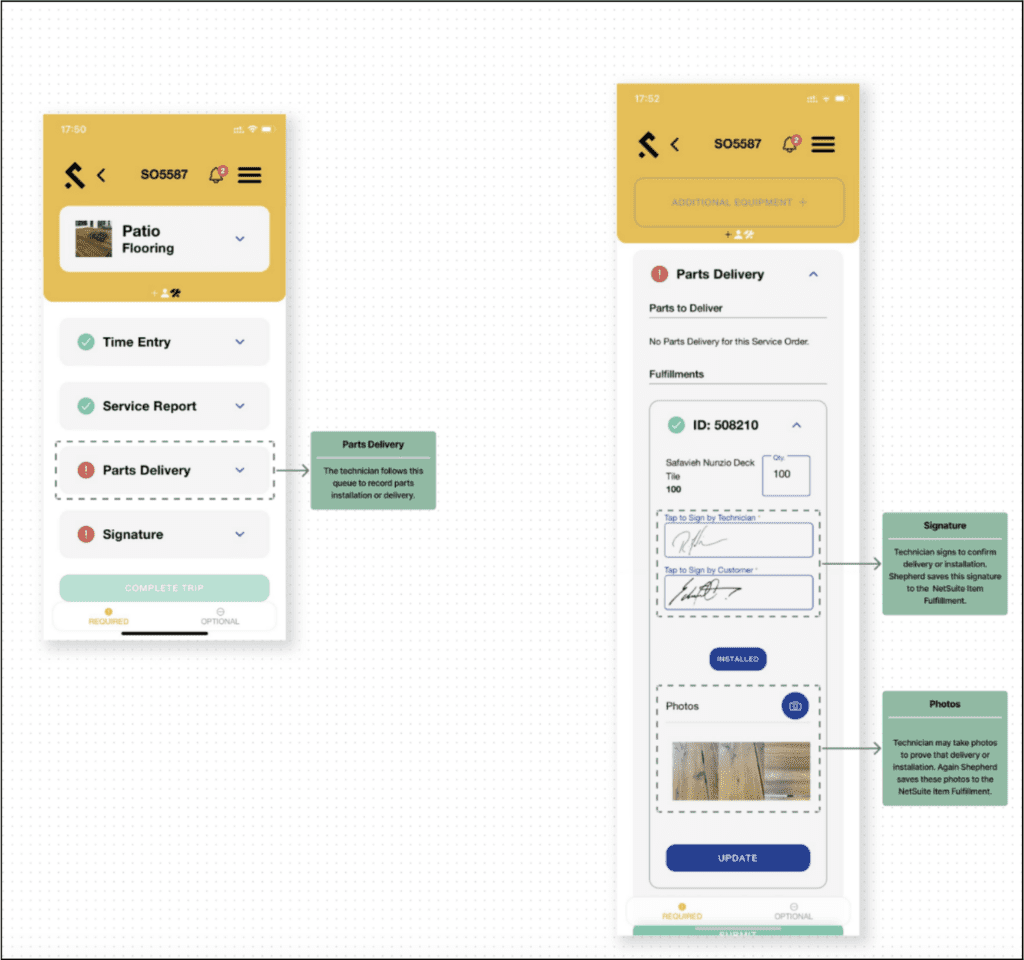

To better accommodate on-site fulfillment/delivery, Shepherd has extended the NetSuite Advanced Fulfillment feature to its mobile application allowing the installer to not only complete the item fulfillment by advancing it through the three stages but also to create a new item fulfillment for any flooring already on the sales order. Many companies choose to have someone in inventory management create the fulfillment through picked and then packed status and then have the installer advance it to the Shipped status in the field. Other companies allow the installer to create the item fulfillment from scratch and advance it through all three states. Your implementer will help you to decide which scenario best suits your organization.

Upon delivery or installation the item changes hands one final time and this ownership does as well.. For that reason, Shepherd also allows for photo capture upon delivery/installation as well as for both installer and customer signatures. Shepherd sends these photographs and signatures to the Item Fulfillment where any other full user may view them in the browser today or years from now. The purpose of these photos will vary but in a worst-case scenario they allow the installer to prove that delivery did, in fact, occur.

Note that signature and photo capture are available independently at each of the three stages of fulfillment: pick, pack, & ship.

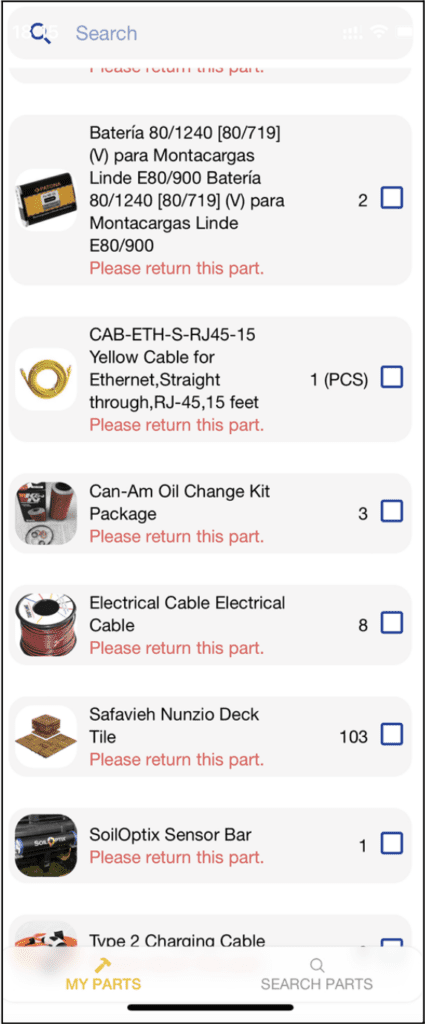

Upon returning to the base after having completed the day’s work, Shepherd reminds installers which parts exist in a surplus in the stock as they are no longer necessary to complete any installation work. Shepherd suggests those quantities as parts return candidates making them available to other installers or for direct shipment in the case of a sale.

Fulfillment photos and signature represent yet another way in which Shepherd extends ERP to the field. There is no synchronization, no integration or third-party database. Every fulfillment photo and signature will live in NetSuite alongside all of your other native data. Save yourself some money in shipping and encourage your installers to deliver your parts.

These two optimizations will help to reduce your business’ inventory needs as well as the frequency of job delay to long lead time.

How often does site work suffer delays due to missing, essential inventory?

Erase that failure with Shepherd.